”Searching for the best possible partner for the complete automation of order execution processes in our company, we ended-up at ZENON AUTOMATION SAICT. It is a Greek company with great experience in the field of order automation and it made a decisive contribution to find the best solutions in relation to our space, the needs of the company and at the same time to implement the project with precision, quality and very good cooperation.”

Achilleas Pavlides

Technical Director, A. PAPANIKOLOPOULOS SA

The Client

The APOSTOLOS PAPANIKOLOPOULOS SA was founded in 1994 and operates in the fields of trading, storage and distribution of medicines, cosmetics and parapharmaceutical products.

The main objective of the company is to constantly improve its services through strategic investments in human resources, technology and know-how, responding to the needs of the modern pharmacy. Its main concern always remains the excellent customer service and the immediate response to their needs, within the ever-changing pharmaceutical industry.

The Need

The pharmaceutical warehouse APOSTOLOS PAPANIKOLOPOULOS SA, which is going through a period of great growth, wanted to modernize its infrastructure in order to be able to respond to the increase in its clientele, the increase in orders and the large volume of work per day that this entails, while continuing to offer a high level services to its customers, executing their orders with accuracy, speed and reliability and keeping their level of satisfaction high.

The company already had an older order fulfillment system, which, however, being limited and partly outdated, had to be expanded and upgraded in terms of its automation, to be able to meet its new increased needs.

The Solution

ZENON AUTOMATION SAICT, a member of Theodorou Group, known for its expertise in the design and implementation of robotics, handling and automation solutions for packaging and the supply chain, implemented a solution adapted to the needs of APOSTOLOS PAPANIKOLOPOULOS SA, which integrates the old system of the company in a new, modern, independent and unified system of fully automatic execution of orders.

This involves 3 distinct stages:

- the automatic collection of orders in boxes using robotic systems

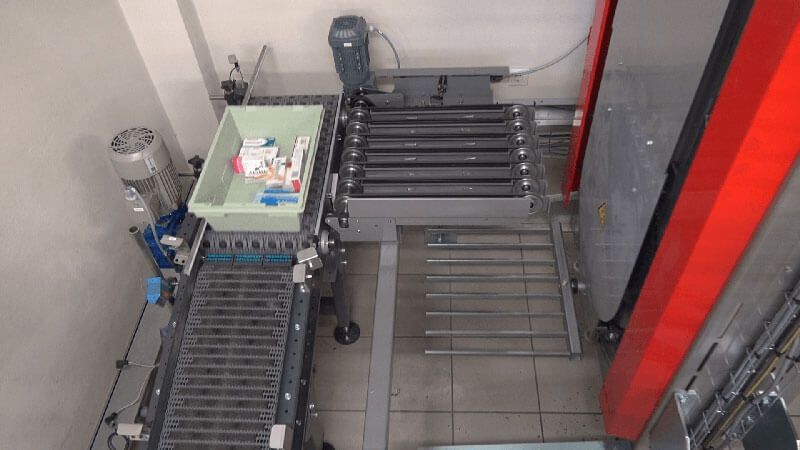

- the automatic handling of boxes within the company

- the automatic invoicing, packing and sorting of orders by route, ready for distribution by the company’s vehicles

In the first stage, there are provisions that manage the empty plastic boxes, small or large, used to prepare the new orders. Then these boxes pass through two modern and fully automatic A-Frame type medicine collection machines of the well-known Austrian company SSI Schaefer, which were supplied and installed by ZENON AUTOMATION SAICT. These machines undertake the collection of the high-speed codes (A) of the individual orders.

In the second stage, after the fast-moving products have already been collected, the boxes are automatically moved from the mezzanine to the ground floor, where the old automatic arrangement, now integrated into the new system, is used to introduce the slower-moving and special products. It is essentially an old-style A-Frame and three manned manual picking stations using portable terminals and inserting the products into the respective boxes.

In the third and final stage the boxes are automatically guided to two automatic printing stations, where the invoice is printed and inserted inside the box, before it is also automatically closed with a lid and sealed with a plastic ring.

The boxes are then sticker-coded with order and customer information and automatically sorted into 16 aisles, depending on which car will pick them up to deliver the orders to customers.

The system also undertakes the automatic handling of the empty boxes returning from the circuit, so that they can be taken to the devices of the first stage and re-supply the system.

The above procedure is carried out 2 or 3 times a day, with speed, correctness in the execution of orders and avoiding delays, which could put the car routes out of schedule.

It was particularly important to implement the project in parallel with the work of the warehouse, so that its operation would not be disturbed at all and the service of its customers would continue uninterrupted.

Thanks to proper preparation and thorough planning by ZENON executives, the individual subsystems that had been tested individually were installed in parts, allowing their completion and transition from the old system to the new in just one weekend without any interruption to the warehouse operation.

The perfect collaboration with EPSILON CSA, which supplied APOSTOLOS PAPANIKOLOPOULOS SA with the line’s ERP & WMS software, played a catalytic role in the implementation.

The Benefits

In a short period of time since the implementation of the solution for the complete automation of order fulfillment processes, its benefits have been immediately seen:

- Errors that were much more likely before in a manual process are now avoided,

- Products are priced and packaged correctly so they can be delivered safely and on time by company cars to pharmacies,

- The company’s customer base, the speed of order execution and the company’s reliability have increased,

- In the same period of time, the company can now cover a much larger volume of customers and orders, having significantly increased its productivity.

At the beginning of each month when there is usually an increased demand for orders in all pharmacies, the company now manages to fully meet this demand by keeping the car timetables, without the need for additional staff that previously existed for these days, thus significantly increasing level of satisfaction of its customers and thus obtaining a competitive advantage and benefit for the company, as pharmacies, depending on the level of service they receive from each pharmacy warehouses, choose which pharmacy(s) warehouses to cooperate with and for which products.

It is also worth noting that thanks to the high level of expertise of ZENON it was possible to upgrade and reuse the old equipment under the central control of the new system. In this way, part of the application’s needs were covered at the lowest possible cost, making the most of the initial investment of the customer who was not forced to decommission it.

Click on the photographs for a larger view:

If you are interested in a similar solution, please call us on tel. +30 210 6690900 or fill out the contact form below.