The Client

The company DIRFYS SA has been active in the drinking water market since 1975, with sales throughout Greece and abroad. It bottles water with modern machines of high technology and productivity, carrying out quality control at all stages of bottling, ensuring excellent product quality. Production is staffed exclusively with engineers, since the demands of the technology applied daily are high. At no point in the production line is human intervention required. Thus, the product is offered directly from the source to the consumer.

The Need

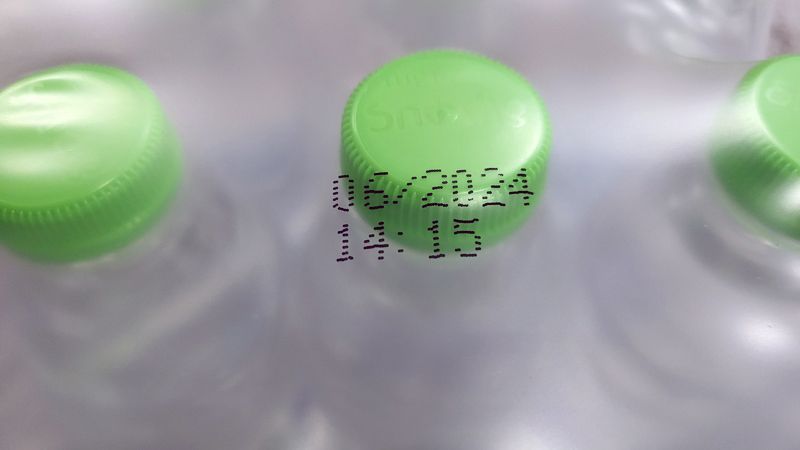

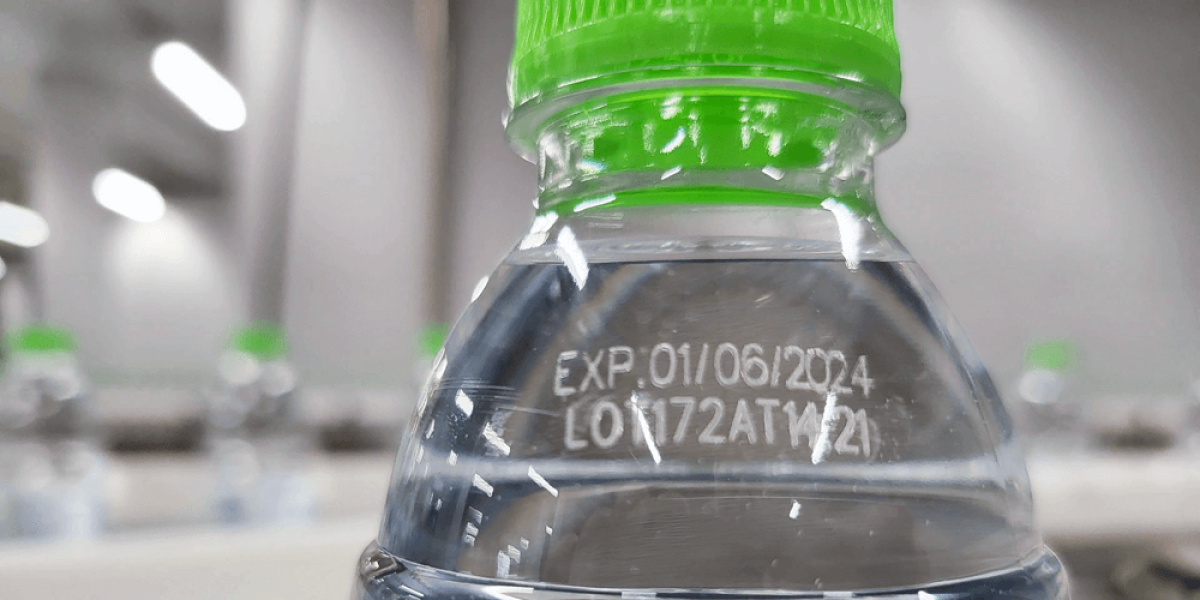

DIRFYS SA was looking for a reliable solution to print the variable information, such as expiration date and production code, on the bottled water packages it produces, in order to achieve high quality printing at high production speeds and an elegant result in the labeling of its products.

The Solution

Responding to this need, Theodorou Group proposed and installed at the DIRFYS SA factory two industrial Domino laser technology printers for the coding of the primary packaging, as well as an inkjet technology industrial printer for the coding of the secondary packaging. In the production line, in addition to the industrial laser printers, appropriately designed bracketing kit was installed, a special safety cage on the print heads to protect the operators and special devices for extracting the fumes created during the operation of the laser printers, in order to maintain the space absolutely clean during their operation.

Industrial laser printers can support printing of variable information on PET bottles at speeds of up to 40,000 bottles/hour, require no consumables to operate, offer high reliability of non-stop operation (99.99% uptime) and enable interfacing with IT factory systems.

The Benefits

- Minimal to zero printing costs of laser printers, due to the non-requirement for consumables

- Fast print speeds

- Reliable non-stop operation

- Quick and easy switching of production programs

- Modern and environmentally friendly printing technology without the use of inks for laser printers

- High quality printing and an elegant result in the marking of the products

- Ability to interconnect with factory information systems

Click on the photographs for a larger view:

If you are interested in a similar solution, please call us on tel. +30 210 6690900 or fill out the contact form below.

Food / Beverages