«The THEODOROU GROUP is able to offer solutions tailored to each individual customer. Based on our specific needs, they designed and installed an automated packing system with a robot in our factory, which increased our productivity by 30%, making us more competitive in foreign markets.»

Dimitris Konstantinou

Factory Manager, E. NEOPHYTOU TRADING CO LTD

The Client

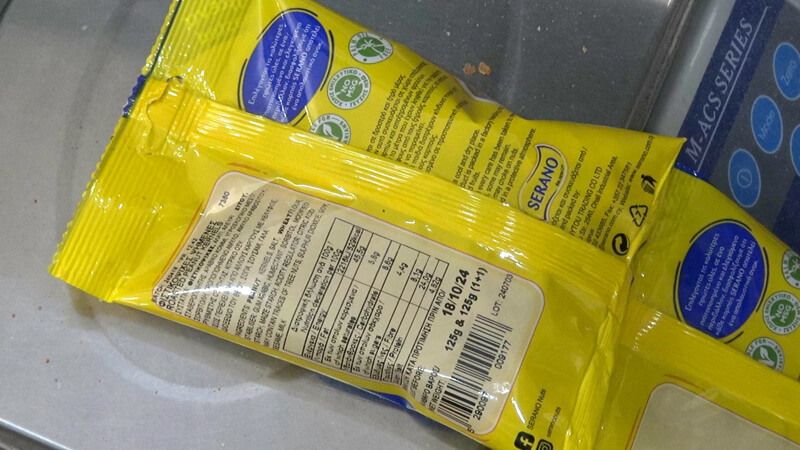

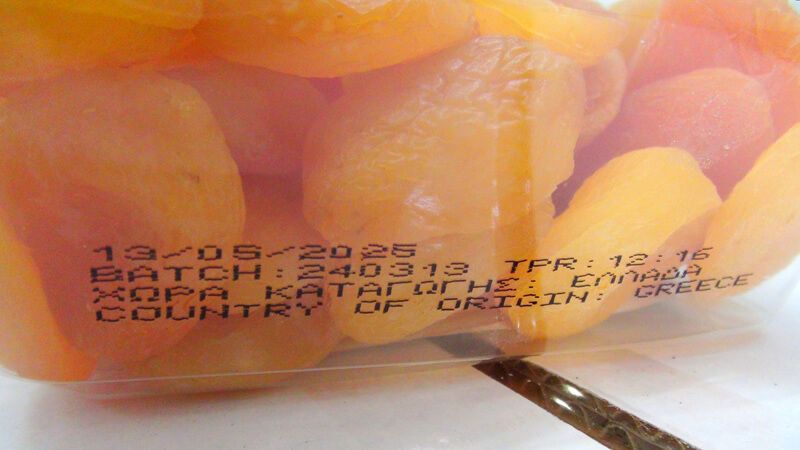

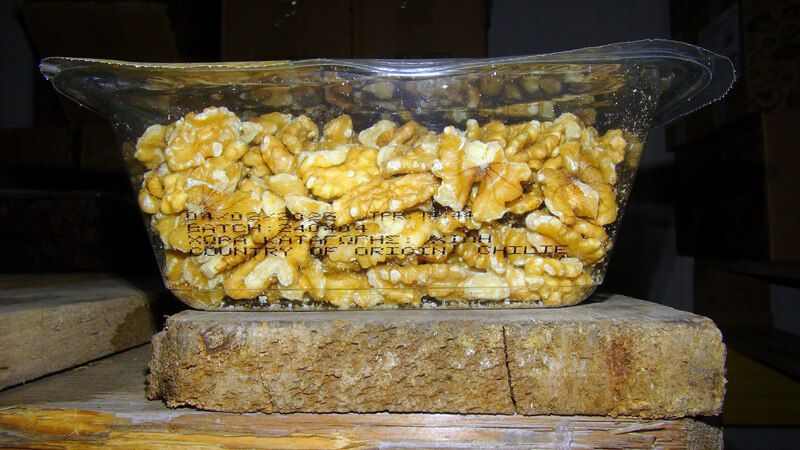

SERANO was founded in 1974 and has since specialized in the production and packaging of nuts. Today, SERANO holds a leading position in the Cypriot market, with its products distributed worldwide in more than 20 countries across Europe, the United Kingdom, South Africa, and soon in China and North America.

The Need

Given its large production volumes, SERANO was seeking a solution for fully automating the secondary packaging processes for two of its production lines. The solution needed to accommodate the high productivity of the lines while maintaining their full flexibility.

ZENON AUTOMATION SAICT, a member of THEODOROU GROUP, having more than 40 years of expertise in the field of end-of-line robotic automation, was asked to design and manufacture a system that could serve a wide range of products in primary packages of various dimensions with the minimum possible adjustments when switching between them.

The system also needed to have the ability to either carton the nut packages into cardboard boxes or group them and shrink-wrap them afterward.

In addition to its flexibility, the system had to occupy the least possible space to allow operators easy access to any point in production while also complying with necessary safety regulations.

The Solution

ZENON designed and delivered to SERANO an integrated and fully automated solution, consisting of two identical hybrid-function robotic systems for secondary packaging (cartoning or shrink-wrapping).

Each system fully meets SERANO’s needs by fully automating the following processes:

For packages destined for cartoning:

- Receiving nut packages (pouches or cups)

- Forming the cardboard boxes

- Grouping the packages according to the cartoning arrangement for each product code

- Inserting the packages into the formed cardboard box

- Moving the box to the sealing station

- Closing and sealing the box with packing tape

For packages destined for shrink-wrapping:

- Receiving nut packages (pouches or cups)

- Grouping the packages according to the desired arrangement

- Stacking the grouped packages in layers

- Shrink-wrapping the groups

Each robotic cell is equipped with a full control panel featuring a touch screen that can store different cartoning and shrink-wrapping programs for each product code. It also supports scalability for the future addition of new product codes. Additionally, the system is equipped with the necessary tools for immediate and effective remote support from ZENON’s experienced technical staff.

All ZENON systems come with a complete safety system that complies with current regulations (CE – Machine Directive) to ensure the safety of personnel and equipment, and they receive the relevant CE certification.

The Benefits

- High productivity

- Reduced operational costs

- Reliability and minimal maintenance needs thanks to the proven design and excellent build quality

- Fast product changeovers due to an innovative approach for interchangeable parts

- Connectivity with the company’s IT systems

- Optimal resource utilization (space, human resources, existing equipment)

- Minimal handling requirements and error reduction

With full respect for SERANO’s production needs, ZENON swiftly and efficiently completed the installation and commissioning of the two systems, thus minimizing downtime for each production line.

Click on the photographs for a larger view:

If you are interested in a similar solution, please call us on tel. +30 210 6690900 or fill out the contact form below.

Food / Beverages

Automatic Case Packing