Dr. Evangelos Theodorou,

Theodorou Group Chairman & CEO

In this article we present the current developments in the two central technologies of the new industrial revolution: the industrial robotics and the new industrial automation . We also give some suggestions on how any industrial enterprise, large or small and medium, could develop a workable strategy for integrating new technologies into its production process.

New trends in robotics

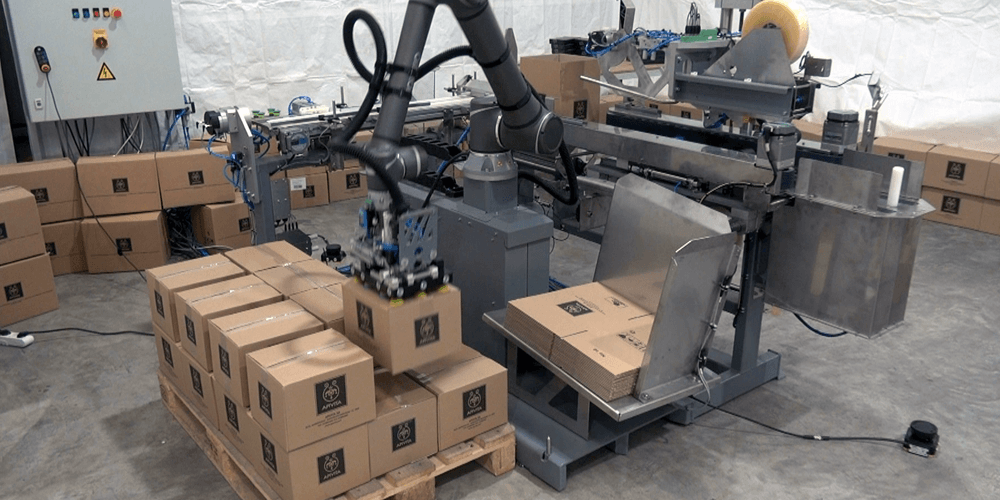

Robots have for decades found applications in industrial packaging, such as automatic palletizing, automatic boxing and most recently in automatic pick and place.

The most important development here is the reduction of costs per robot and the availability of standard robotic modules for specific applications. The result is the ability to introduce robotics to smaller and smaller companies, something that seemed unreal a few years ago.

Another development is the availability of intelligent space sensors that allow robots to perform more and more “difficult” functions.

A new trend is the ability to move the robot itself instead of remaining static in some position. This way the robot can serve more lines or more functions, which achieves greater economy.

Despite their cost reduction, robots are becoming faster, positioning accuracy and repeatability are increasing, while their drivers are becoming smarter and offer much more flexibility and interface with other robots, with central information systems, in other words robots are now an integral part of the digital factory. Other developments include the appearance of CoBots (Collaborative Robots), ie small robots that can work harmoniously with pilots without the risk of injury to humans, but also the extension of the term robot to include more general systems (with or without movement) automatic performing operations inside the factory. This new vision is essentially the extension of robotics to the realms of automation, in which computers and digital technology are playing an increasingly important role.

New trends in industrial automation

Classical automation, which has been with us for the last decades, has made it possible to optimize the functions of the various machines involved in the production processes. The new automation allows machines to communicate with each other and synchronize in such a way that their overall productivity can be improved. And of course, improving productivity requires further interconnection of production with other business systems, such as sales, raw material warehouses, finished products, accounting and so on. which have been largely digitized in recent years.

The new automation can be applied to any production process involving machinery, digital systems and human resources, with more typical examples being industrial companies, storage companies and supply chain companies in general.

Applications and benefits

It is clear that new technologies now give us enough tools to develop applications that can give a significant boost to production processes. It is almost impossible to list all these applications, but we can categorize them as follows:

- ON LINE monitoring and measurement of the production process, possibility of automatic and remote interventions

- Optimal planning, synchronization of functions, increase of productivity, reduction of costs

- Upgrading the role of employees and improving their safe working conditions

- Flexibility and faster product changes

- Reduction of energy costs

- Improving the operation of the supply chain and its interconnection with industrial production and packaging

- Traceability, product quality and meeting the requirements of customers, end consumers, government agencies

- Electromechanical equipment maintenance procedures, ensuring greater reliability and higher efficiency

The real opportunity

In addition to the applications and benefits of new technologies, the real opportunity given to companies is the ability to change the mentality of its people and how to deal with business operations.

Some examples:

- New technologies bring closer parts of the business that have traditionally operated independently, if not competitively. Production, technical management, IT, supply chain, procurement, quality control must learn to work more closely together. The role of the “multi-engineer” begins to appear, ie the engineer who understands and handles different technologies, mechanical, electrical, electronic, IT, telecommunications and automation. At the same time, corresponding requirements are developed by the external partners. The new type of Systems Integrator must have in-depth knowledge of all the above technologies in order to be able to help the company in its transformation towards the new industrial revolution.

- Traditionally, every business is called to meet the needs of the market in the best way. New technologies can help a company offer something much more important: products and services that shape new trends and consumer habits. The companies that will offer such innovative added value are the ones that will prevail in the new business landscape.

Implementation proposals

Each company is called upon to draw up its own strategic plan for its transition to the new era. However, each project must take into account the following rules:

- Transformation is an ongoing process and must be done step by step. Once the successful introduction of one step is done, then we move on to the next, which we must have planned in advance.

- Not technology for technology. Technology only gives us tools for applications. The application of technology is the demand for every business.

- Technologies are changing and evolving very fast as opposed to central design which has to change at a much slower pace. No business wants to have equipment that does not meet its current needs. A modern approach to this big problem is SERVITIZATION, which allows the use of equipment in the form of service (Pay Per Use Model).

- The role of the staff must be constantly upgraded and the repetitive and standardized functions must be gradually assigned to the machines.

Conclusion

The new industrial revolution is here and no business can afford to ignore it. The good news is that the road to transformation is now paved, as long as businesses address the issue with due diligence and make sure they are informed by sources who have proven experience in applying new technologies.

Dr. Evangelos Theodorou is the President & CEO of Theodorou Group. He holds a degree in Electrical and Mechanical Engineering – NTUA (National Technical University of Athens) and holds a Ph.D. in Electronic Systems from the University of Cambridge, England. He has been a lecturer at the Department of Electrical and Mechanical Engineers of the NTUA.

Dr. Evangelos Theodorou is the President & CEO of Theodorou Group. He holds a degree in Electrical and Mechanical Engineering – NTUA (National Technical University of Athens) and holds a Ph.D. in Electronic Systems from the University of Cambridge, England. He has been a lecturer at the Department of Electrical and Mechanical Engineers of the NTUA.