Dr. Evangelos Theodorou

Theodorou Group Chairman & CEO

The ability to fully and reliably trace products is a fundamental requirement for the proper operation and transparency of any supply chain. This traceability must be carried out at every stage of the production process (internal traceability) as well as throughout the supply chain until the product reaches the final consumer (sequential traceability).

Each participant in the supply chain has an immediate and pressing interest in traceability. Specifically:

- Production units to ensure that in the case of a fault, they can quickly locate defective products.

- Those involved in the handling and distribution of products to ensure that the products have been handled correctly.

- Regulatory Authorities to monitor the proper functioning and transparency of the supply chain.

- Consumers to ensure that the products they purchase are genuine and of high quality.

Traceability in the Era of Industry 4.0 and Logistics 4.0

Although the needs and requirements for traceability have been recognized and in place for many years, all stakeholders have faced significant difficulties in implementing traceability because full traceability requires specific technological tools and applications that ensure the monitoring of daily processes.

In today's era, where Industry 4.0 and Logistics 4.0 solutions are widely available, these difficulties can be easily overcome. Let’s recall some of these solutions: Big data exchange and analysis, interconnected automation, smart robotics, cloud computing, 5G, IIoT, smart cameras and sensors, advanced coding systems with Serialization, Aggregation, etc.

Below we provide more details about the Serialization and Aggregation technologies, which are relatively new and are now beginning to find applications in the industry.

Serialization Systems

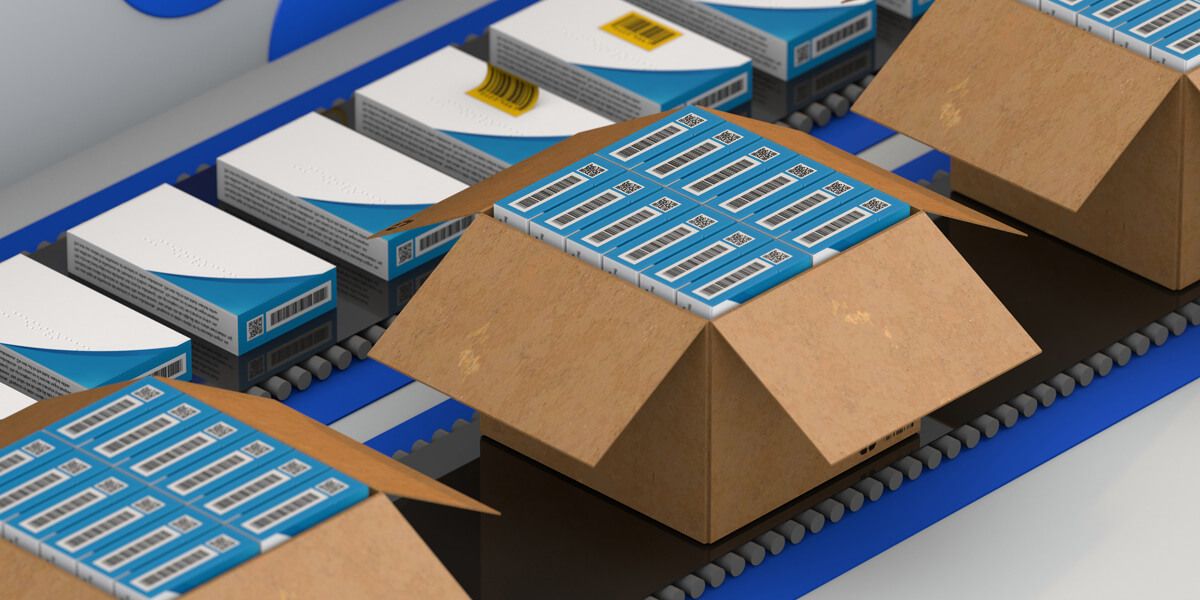

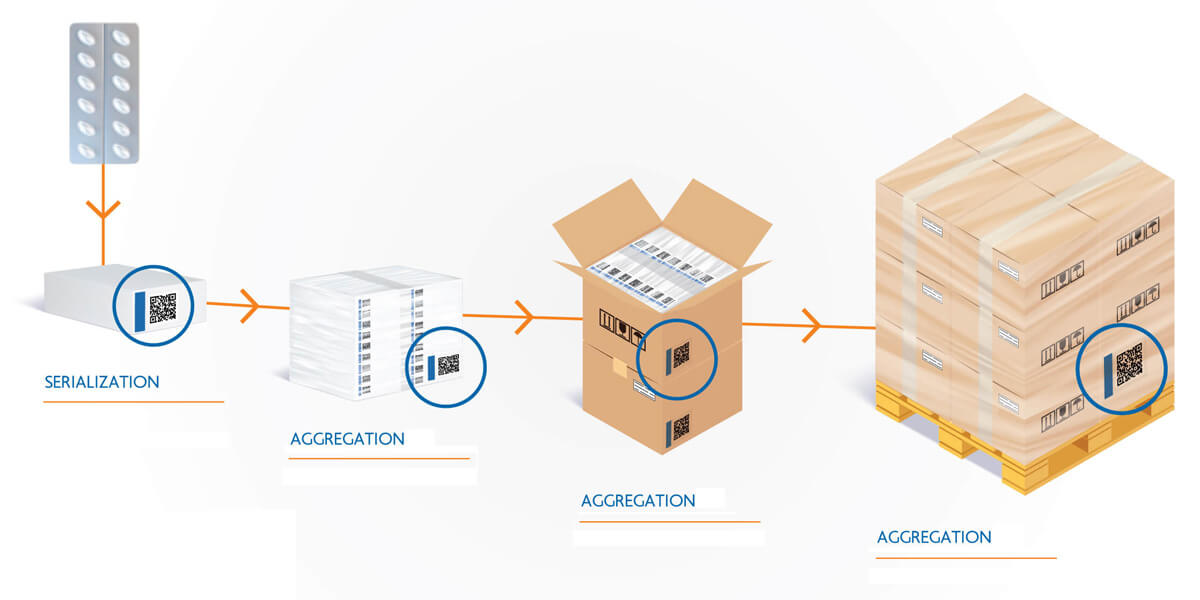

The term SERIALIZATION refers to the identification of each product individually through marking it with a unique number (identification code). This marking takes the form of a two-dimensional (2D) code, which must be placed on the product packaging during the production process. This can be achieved either by directly printing the 2D code on the packaging or by using a label that is printed with the 2D code when it is applied to the product.

A SERIALIZATION system consists of 3 parts:

- An information system designed to "generate" the unique serial codes, which must exchange data with the ERP system and other information systems of the factory and supply chain.

- The printing system, which may consist of code printers (inkjet, laser, thermal, etc.), or PRINT & APPLY printers in the case of label usage. These printers must have printing speeds that match the production line speeds and must also have the capability to exchange data ONLINE with the information system supporting SERIALIZATION.

- The system to check the correct printing/application of the unique serial numbers on the products. This system must have the ability to exchange data ONLINE both with the printing system and the information system supporting SERIALIZATION.

Aggregation Systems

The term AGGREGATION refers to the ability to identify the unique SERIALIZATION numbers contained in each group packaging of products (boxes, pallets). The AGGREGATION system has the same structure as the SERIALIZATION system, and these two systems must work together, exchanging data ONLINE and in real-time. It is emphasized that AGGREGATION is critical for the operation and transparency of the supply chain, given that products are transported in their group packaging.

Structured Supply Chains

Serialization and Aggregation systems have been fully implemented in the supply chains of pharmaceuticals, explosives, and tobacco products. In the beverage industry, the LOTIFY system will soon be implemented, while in consumer products distributed through retail stores, the GS1 DIGITAL LINK system has been proposed. Although both of these systems are not purely SERIALIZATION and AGGREGATION, they can significantly contribute to traceability and transparency within the supply chain.

Dr. Evangelos Theodorou is the President & CEO of Theodorou Group. He holds a degree in Electrical and Mechanical Engineering – NTUA (National Technical University of Athens) and holds a Ph.D. in Electronic Systems from the University of Cambridge, England. He has been a lecturer at the Department of Electrical and Mechanical Engineers of the NTUA.

Dr. Evangelos Theodorou is the President & CEO of Theodorou Group. He holds a degree in Electrical and Mechanical Engineering – NTUA (National Technical University of Athens) and holds a Ph.D. in Electronic Systems from the University of Cambridge, England. He has been a lecturer at the Department of Electrical and Mechanical Engineers of the NTUA.