News

Read our latest news (Announcements, Articles, Exhibitions, Campaigns, Presentations, Conferences)

- Home

- News

Implementing Industry 4.0 & Logistics 4.0

The Theodorou Group has installed numerous digital transformation systems for industry and supply chain management, both in Greece and abroad. From our experience, we have concluded that most businesses are eager to begin their digital transformation journey. Theodorou Group has a team of specialized digital transformation consultants who can help you in this process.

The Industry 4.0 Applications

It is a fact that there is a lot of information about the new industrial revolution and the technologies that support it. Knowledge of these technologies is essential for industry executives who are responsible for developing strategies for integrating digital transformation. The question, of course, is how technologies lead to applications that provide real solutions to the problems facing the industry.

Connected Factory Application in a Food Factory

Watch the presentation video of the connected factory application we implemented in a food manufacturing plant. This application integrates the full range of Industry 4.0 technologies and serves as a model of digital industrial transformation. It achieves ERP integration with production, was completed in a short time frame, and the estimated payback period for the investment is less than 12 months.

New Technologies of Theodorou Group at FoodTech 2021

At FoodTech 2021, we showcased a range of new packaging and logistics automation technologies. Specifically, we presented labeling systems, our new IN-LINE checkweiging weighing and dimensioning systems, automated pallet handling systems with cobots, end-of-line automation systems and our successful equipment rental and old equipment disposal programs.

New Trends in Robotics and Industrial Automation

In this article we present the current developments in the two central technologies of the new industrial revolution: the industrial robotics and the new industrial automation. We also give some suggestions on how any industrial enterprise, large or small and medium, could develop a workable strategy for integrating new technologies into its production process.

New Construction Department of Theodorou Group

Theodorou Group completed the creation of a new construction department for the development of advanced industrial weighing systems, checkweighers and automatic titration on the production line. This new activity of the Theodorou Group was carried out with the transfer of know-how from Mettler-Toledo and Garvens, with which the group already has a long-term cooperation.

New Trends and Technologies in Packaging

Product packaging is a central priority of every industrial enterprise. This is because, during this critical phase, the product is prepared for its journey through the supply chain and is presented in a way that appeals to the final consumer. In this article, we look at the trends that are impacting packaging and highlight the innovative technologies designed to address the evolving needs of the industry.

Welcome to the Connected Factory Age

The Theodorou Group developed the Tracer Factory suite to address the need for real-time monitoring, control, and assurance of quality, productivity, and safety in factories. The Tracer Factory suite can be integrated with other information systems within the factory, but its primary capability is to connect and interact with a wide range of equipment on the production floor (shop floor).

Zenon Automation at the Technology in Action 2021 Conference

Zenon Automation SAICT participated in the online virtual conference Technology in Action 2021, organized by Boussias Communications on May 20, 2021. The purpose of the conference was to present practical applications of technology to companies and organizations, for retail stores, sales, purchasing, production, storage, distribution, human resources and data analysis.

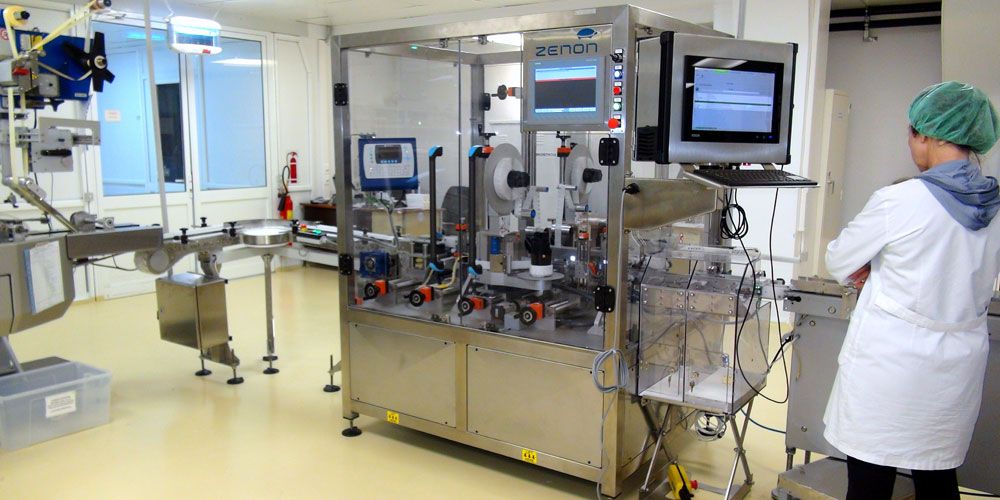

Industry 4.0 Solutions for the Pharmaceutical Industries

With more than 40 years of experience, we can claim that we know the special requirements of the pharmaceutical industry and we can offer the applications that best meet these requirements.In our modern facilities 11,000 sq.m. in Peania, our 95 experienced technicians design and build applications that are fully adapted to the special requirements of our customers in Greece and abroad.

Inkjet and TTO Codes Printing with a Moving Head

The evolution of industrial inkjet and thermal transfer overprinting (TTO) code printers, combined with high-speed printhead movement mechanisms that do not compromise the printer’s reliability or print quality, enables the printing of codes on packaging machines that handle a large number of products simultaneously. See a video from one of our applications.

Zebra ZT411 and ZT421 Thermal Printers

Theodorou Automation SAICT in collaboration with Zebra, presents in the Greek market the new series of industrial thermal printers ZT411/421. Equipped with a large 4.3 “color touch screen and autonomous use due to the built-in dual USB Host, the new Zebra printers set new standards in print quality, reliability, and advanced connectivity. The new printers are TF Ready®.